The Definitive Guide to Metal Infill Panels

Table of ContentsGet This Report about Metal Infill PanelsMetal Infill Panels - TruthsOur Metal Infill Panels Statements

The infill wall surface is the supported wall that shuts the boundary of a building created with a three-dimensional framework structure (normally made from steel or reinforced concrete). Consequently, the architectural frame makes certain the bearing feature, whereas the infill wall offers to divide inner and deep space, filling packages of the outer structures. The infill wall has the unique fixed function to birth its own weight. The infill wall surface is an exterior upright nontransparent kind of closure. Relative to other groups of wall, the infill wall surface differs from the dividing that serves to divide two indoor spaces, yet likewise non-load bearing, and from the lots bearing wall.

Making use of masonry infill walls, and also somewhat veneer wall surfaces, particularly in enhanced concrete frame frameworks, prevails in lots of countries. Actually, making use of masonry infill wall surfaces provides an affordable and long lasting solution. They are simple to construct, attractive for design and also have a very effective cost-performance. Today, stonework enclosures as well as dividing walls are primarily constructed from clay units, however additionally aggregate concrete systems (thick and light-weight accumulation) and autoclaved oxygenated concrete devices are used. A lot more lately, industry is likewise attempting to present timber concrete blocks. Dividers wall surfaces, made with both up and down and flat perforated clay blocks, stand for two-thirds of the corresponding market - metal infill panels.

The security versus fire is just one of the requirements that is commonly called for to enclosures walls - metal infill panels. Nonetheless, as typically the extra typically utilized products (blocks, find out here now blocks and mortar) are not fuel products, it is reasonably easy to achieve the demands relating to the limitation of spread of fire, thermal insulation and also structural strength, which in severe cases, must be guaranteed for 180 minutes.

The Best Guide To Metal Infill Panels

The thermal convenience is a need that the enclosure wall surfaces need to comply. This requirement has a straight influence on the construction why not try this out of the wall surfaces. The thermal laws are demanding significantly higher values of thermal resistance to the walls. To fulfill these demands brand-new products and structure systems, which guarantee that the thermal resistances asked for by the guidelines will be given, are established. It is most likely that in the near future traditional building and construction services with dual leaf wall surfaces (with new, extra thermally effective blocks as well as blocks) will certainly be adapted, and also there will be boosted use thermal insulation systems for outside (ETICS), such as use single fallen leave walls.

The development of new enclosure wall systems should, besides attempting to boost requisites relating to structural stability in situation of quake, boost the thermal resistance of the solution.

When there is the perimeter call in between the masonry infill wall surfaces and the frame, in average circumstances of adherent robust infill wall surfaces, the impact of tightness increase (as well as likewise dissipation) influences the structure response. When it comes to infill wall surfaces built detached from the structure (not in adherence with the framework components), it is likely that infill wall surfaces serve as an added mass put on the framework just, and must not have other considerable results. As a whole, in one of the most frequent situation of perimeter get in touch with in between the masonry panels as well as the light beams and columns of the RC structure, the infill panels connect with the structure, no matter of the side resistance capacity of the structure, and also imitate structural elements, surpassing side loads up until they pop over to this site are severely damaged or ruined.

The major problems in the regional communication in between frame as well as infill are the development of brief beam, short column impact in the architectural elements. The zones in which auxiliary shear forces can occur, acting locally on the extremities of the beam of lights and also columns, should be dimensioned and transversally strengthened in order to surpass securely these pressures.

The 2-Minute Rule for Metal Infill Panels

A wall surface without a dental caries or constant vertical joint in its aircraft.

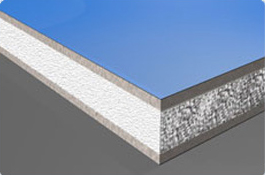

A wall surface being composed of 2 identical single-leaf wall surfaces, effectively tied with each other with wall surface ties or bed joint reinforcement. metal infill panels. The space in between the leaves is left as a constant cavity or loaded or partly filled up with non-loadbearing thermal insulating product. A wall surface consisting of 2 fallen leaves separated by a cavity, where among the fallen leaves is not contributing to the strength or rigidity of the various other (possibly loadbearing) fallen leave, is to be pertained to as a veneer wall.

A wall made use of as a dealing with however not bonded or contributing to the stamina of the support wall or mounted structure.